One device, so many possibilities

Recently, there has been a strong growing demand for honey. This is great news for beekeepers. The boom in the market allows for increasing sales and raising rates. Growing consumer awareness and the demand for healthy food allow us to believe that it will be a constant trend. It is also a challenge. It is important to work more efficiently and in more comfortable conditions. Thanks to this, with less effort and time, it will be possible to achieve more ambitious goals. It is particularly time-consuming to uncap the combs in order to prepare them for honey extraction. However, thanks to the automatic Konigin uncapper, this activity does not present even a fraction of the difficulties associated with the traditional method of performing this work.

The universal solution with high performance

The automatic uncapping machine is a solution that allows uncapping up to 400 plasters per hour of work! This result will meet the needs of the owner of a large apiary. At the same time, it is an option that will save a lot of time for owners of smaller and medium-sized farms who want to spend more time working directly with the bees. The uncapper's versatility also includes a wide range of possible adjustments. Not only can the uncapping speed be adjusted to your needs, but also the width of the dispenser. You can also manually adjust the width and angle of the knives. These are heated by circulating water. The device has a tank with a capacity of 5 l and a heater with a power of 0.8 kW. So the blades heat up quite quickly, and then the device maintains their elevated temperature. As a result, the cell caps are sheared smoothly and their walls are not frayed. After centrifuging and returning them to the hive, such honeycombs are quickly refilled with honey by the bees.

A wide range of applications

The automatic uncapper can work in an automatic line. Such a harvester uncaps the honeycombs, empties them of honey, recovers another batch of honeycombs, cleans them and finally pumps them into containers. This is a variant for those beekeepers who have the highest requirements for the processing capacity of the apiary. The automatic uncapping machine, however, also fits perfectly with the cappings extruder and the track for slices with a drip tray. This is an interesting option for owners of large, efficient honey extractors. Thanks to the rapid detachment of the patches, you can fully use the potential of advanced extractors with large baskets and large drums. The automatic uncapping machine can furthermore be aggregated with a conventional uncapping table. Then, however, it will only act as a drainer, because uncapping the beekeeper will be performed by an automatic Konigin device, saving it a lot of time and work.

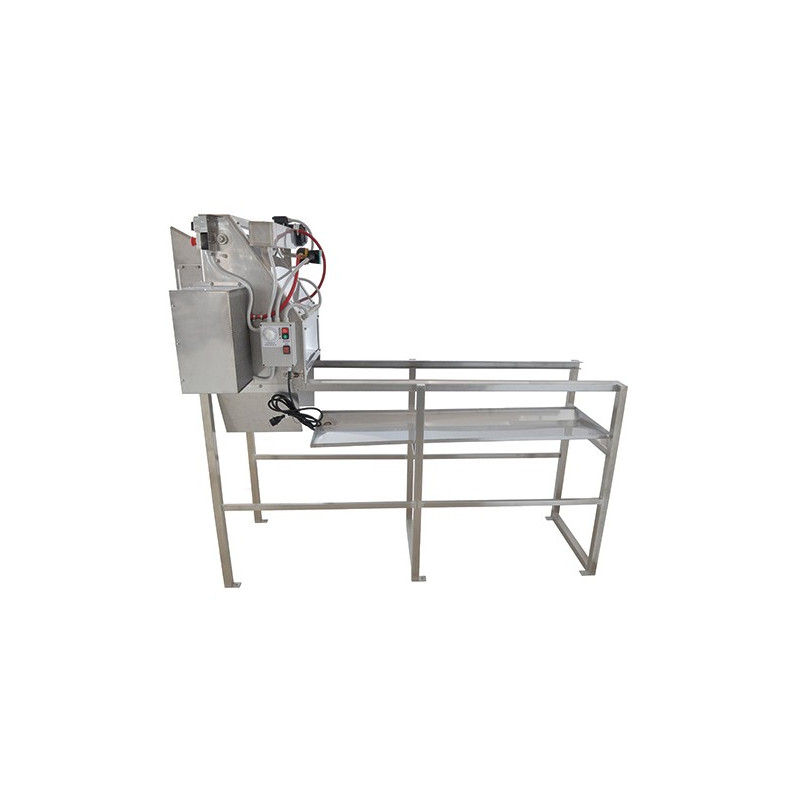

Ease of use, trouble-free use of the highest quality device

While the automatic uncapper has so many uses and offers impressive possibilities, it is surprisingly easy to use. It has an intuitive driver. Even for a person with low technical predispositions, it will not take longer than a minute to learn about its operation. The uncapper motor uses only 0.18 kW of electricity, and the whole thing is relatively compact. The device, depending on the configuration variant with other equipment, will fit almost any beekeeping studio. The user's tasks are also simple: take care of loading the device with slices, provide space for uncapped slices, centrifuge them and enjoy the flowing sweet and aromatic stream of honey filling subsequent containers, and also the apiary's pocket.

The uncapper does not block the frames, the width of the feeder can be adjusted.

Possibility of manual adjustment of knives, width and inclination

Heated knives with water - 5l tank. (closed circuit) power 0.80 kW.

Automatic frame feeder (additionally the possibility of speed control).

Uncapping engine power 0.18 kW.

Loading track (2m long).

Performance: up to 400 frames.

No customer reviews for the moment.