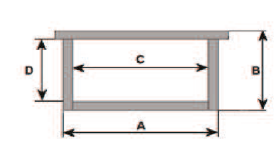

max frame height (B) - 260mm, (DADANT, 16 x 1/2 DADANT)

AUTOMATIC CONTROLLER

.png) Security policy(edit with the Customer Reassurance module)

Security policy(edit with the Customer Reassurance module) Delivery policy(edit with the Customer Reassurance module)

Delivery policy(edit with the Customer Reassurance module) Return policy(edit with the Customer Reassurance module)

Return policy(edit with the Customer Reassurance module)Premium Standard cassette honey extractor.

Professional equipment for demanding beekeepers

Where the expectations towards the equipment are the highest, the cassette honey extractor is the best choice. It combines the advantages of radial and diagonal honey extractors. The frames once inserted into the drum do not need to be changed, and their spinning in a direction parallel to the wall of the device makes the cells completely empty after a few minutes.

Who is the cassette honey extractor the best choice for?

You could say that for everyone. It is a very professional device, for some reasons the most perfect of the commonly used variants. The extraction of honey from the frames takes place here in three stages. After loading the batch and starting the device, the frames are spun in one direction. The basket mechanism makes the cassettes position themselves parallel to the wall of the honey extractor under the influence of centrifugal force. This location promotes faster cell emptying. However, the honey collected on the other side is pressed against the comb, so in order to prevent the wax from breaking, only a part of its content is centrifuged from the first side. The basket then automatically changes its direction of movement. This causes the cassettes to turn 180°. And in a second step the honey on the other side of the same frames is centrifuged, this time whole. The third stage is to return to the original direction of the basket movement in order to completely empty the honey from the combs.

Construction

Apart from the thickness of the materials used in the construction of the machines, the construction of the basket of cassette honey extractors and the reinforcement of the drum deserve attention.

The cassettes are not connected to each other by springs in their upper structure. In Konigin cassette honey extractors, each cassette is separately equipped with a system of guides, to which stainless springs have been installed. Mounted below the bottom structure of each cassette, this system allows the cassettes to return to their original position during automatic changes of direction. Thanks to this solution, Konigin cassette honey extractors are much more convenient during washing and reliable during spinning. A novelty and an additional advantage of Konigin cassette honey extractors is the strengthening of the basket of honey extractors in the lower structure. The welded 'star' above the guide system is made of laser-cut elements. The new solution of the cassette system additionally strengthens the basket structure and, most importantly, eliminates `` waving '' during spinning. The applied cage reinforcement translates into the service life of the mounted bearings. The cassettes are made of wires with a diameter of 2mm and the clearance between the wires on the basket structure is only 10mm. We guarantee that even bright, fresh combs do not cut into the construction of the cassettes, which translates into the preservation of the highest quality combs after centrifuging the honey.

Another structural element that distinguishes our company from the competition is the welded drum reinforcements on the inside at the top of the honey extractor and the external reinforcement of the drum below its bottom edge. Welded drum reinforcements replace the traditional hoop that holds the honey extractor drum in the upper structure and eliminate the cross that strengthens the honey extractor mounted below the bottom. Apart from the fact that the traditional solutions of the barrel reinforcements of honey extractors are usually painted, their structure is fastened with screws. The standard solution of drum reinforcement will never match the welded elements, because the reinforcement is part of the structure and not an addition.

Outside the competition, the use of only stainless steel on the entire structure confirms that Konigin honey extractors are devices of the highest quality. All honey extractors, regardless of their size, are made in the same way, using the highest quality elements of steel and stainless steel.

Automatic control

Each cassette honey extractor from the Konigin portfolio is equipped with an automatic control, the centrifugation process takes place without the participation of the beekeeper, but only according to a 3.5, 7 or 9-minute program selected by him. The biggest benefits of a cassette honey extractor are labor savings. It is limited to inserting and removing the frames from the drum. The precision of honey extraction is close to 100%. An additional advantage of the Konigin automatic controller is the possibility of manual interference with the maximum speed during spinning. In an emergency, when the weight distribution of the frames differs from cassette to cassette, e.g. an excess of propolis in relation to each of the spun frames, it may turn out that the maximum speed of 400 revolutions per minute is too high. Therefore, in a very easy and quick way, using manual adjustment, you can set the speed appropriate for the spinning cartridge, usually at the level of 70-80% in relation to the maximum speed, it is enough to complete the spin without the need to stop the machine.

Data sheet

Specific References

No customer reviews for the moment.